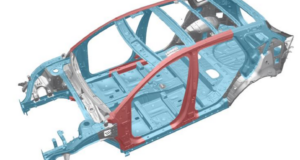

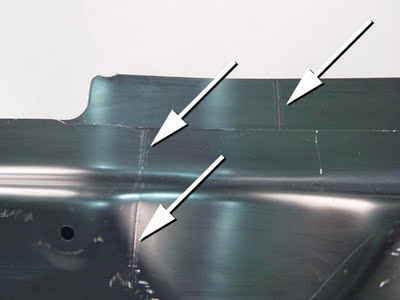

Simple! Look at the image below and think of it painted. We could easily overlook the fact that this B-Pillar structure is made up of 3 different blanks and two different gauges of materials. How will you know that you are dealing with a tailored blank?

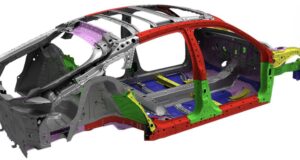

Look at the image below with the white arrows. The arrows are pointing to laser welds. Laser welds are suited to tailored blank production as they are very narrow, have no raised top- or under-bead and do not require special finishing.

The B-Pillar on the 2004 Ford F-150 below uses a tailor-welded blank.

Below you can see where the white arrow is pointing to zoomed in. On this B-pillar, the thicker and stronger steel is below the laser weld.

Tailor-welded blanks allow combining different strengths of steel in one part without adding complications at the joints. Watch for this design method to be used more with each model year.

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles