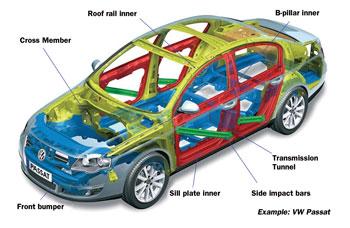

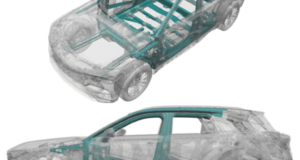

Hopefully everyone understands how many Boron and UHSS parts are made from a hot blank. If not, Boron and other UHSS are too hard to be stamped into the shapes and forms required by automakers. To solve this problem, a process called Hot stamping and quenching, also known as press hardening, is used. This process can increase the tenssile strength of the material by 150 percent (from 600 MPa to 1,500 MPa). The most suitable components for the process as shown here on the VW Passat® are side impact bars, roof rail inner, front bumper beam, B-pillar reinforcement, sill plate inner, and transmission tunnel.

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Flaunting the class, looks, quality and safety Volkswagen is known for this new saloon.. This vehicle looks stunning …