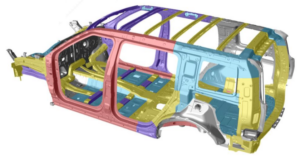

The steel makers are responsible for all the new challenges firefighter face with vehicle extrications. However, groups like the American Iron and Steel Institute have made information available that we should all take the time to read.

Technical Information

- Application and Repairability of Advanced High-Strength Steels

Presentation highlighting the use, growth and repairability of advanced high-strength steels in automotive applications. - Advanced High-Strength Steel Applications Design and Stamping Process Guidelines – A Special Edition of In-Depth Advanced High-Strength Steel Case Studies (36MB)

The AHSS Applications Guidelines Group of the Auto/Steel Partnership (A/SP) has conducted several in-depth case studies of Advanced High-Strength Steel (AHSS) stampings for automotive structural components and has provided summaries of those studies and lessons learned in this manual - The Challenges of Advanced High-Strength Steels at Rescue and Extrication Incidents

An overview of current field research being conducted by fire service personnel in concert with major auto insurers on specific vehicle rescue techniques and procedures. - ULSAB: Engineering Report – Full Report

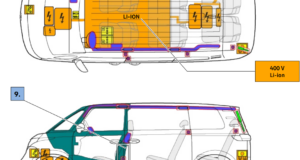

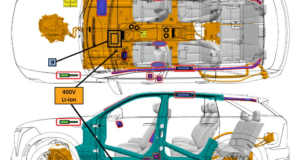

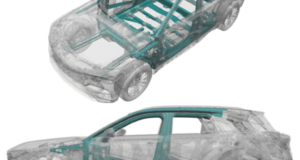

The complete engineering report detailing ULSAB and the intensive, multi-phase study that demonstrates steel’s capability to reduce the weight of a vehicle’s body structure and, at the same time, ensure safety with improved comfort and driving performance, all at affordable cost. ULSAB resulted in the design and engineering of a lightweight, efficient steel body structure that achieves impressive mass savings and significant performance improvements, while retaining affordable cost to manufacture. - ULSAB-AVC Overview Report: Full Report

The ULSAB-AVC Overview Report showcases the latest high-tech steel grades for automotive applications. Combined with innovative design and the latest manufacturing processes, the advanced high-strength steels (AHSS) are key enablers of highly efficient vehicle structures capable of delivering exceptional fuel economy and safety performance at affordable cost. - Steel Bumper Systems for Passenger Cars and Light Trucks – Revision 3: Full Report (4.7MB)

A recently updated Bumper Design Manual guides automotive engineers through the latest in materials and manufacturing innovations. - Vehicle Crashworthiness and Occupant Protection Book (Full Book – 10MB)

A book that combines structural crashworthiness, safety features, simulated technology and design safety information in a single publication for the convenience of the safety engineer. - ULSAC: Engineering Report – Full Report

Demonstrates that using steel as the material of choice in conjunction with the utilization of current and advanced manufacturing processes, could produce closures, which can achieve a 10% mass reduction, while maintaining structural performances at no cost penalty. - Advanced High-Strength Steel Repairability Report – Phase I

A study highlighting the development of appropriate repair procedures for 600 MPa tensile strength (TS) dual-phase steel and a 1300 MPa TS Martensitic steel, after exposure to typical repair arc welding and flame straightening temperature cycles. Phase I outlined recommended practices for repairing components made of these advanced high-strength materials. - Advanced High-Strength Steel Repairability Report – Phase II

A study illustrating the repair procedures for advanced high-strength steels, such as DP 780, TRIP 600, and TRIP 780. Phase II addresses the effect of MIG repair welding on the mechanical properties of DP and TRIP steels to validate welding as a means to repair crash damage that cannot be repaired by conventional flame straightening. - Characterization of Fatigue and Crash Performance of New Generation High-strength Steels for Automotive Applications – Executive Summary

This report highlights fatigue and high-strain rate data for a new generation of high-strength sheet steels, including Dual-Phase (DP) steels, Transformation Induced Plasticity (TRIP) steels, Bake Hardenable (BH) steels and conventional High-Strength Low Alloy (HSLA) steels.

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles