Why do we skin doors? Have you ever wondered why your door removal went from bad to worse? The outer skin or panel of the door is usually composed of light-gauge steel which all of us know can separate from the inner door structure during a door removal. Why does this happen? Two reasons, bad technique or the design of the door. Usually we find out it was our technique.

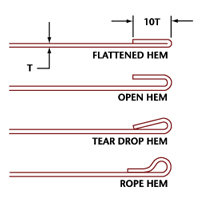

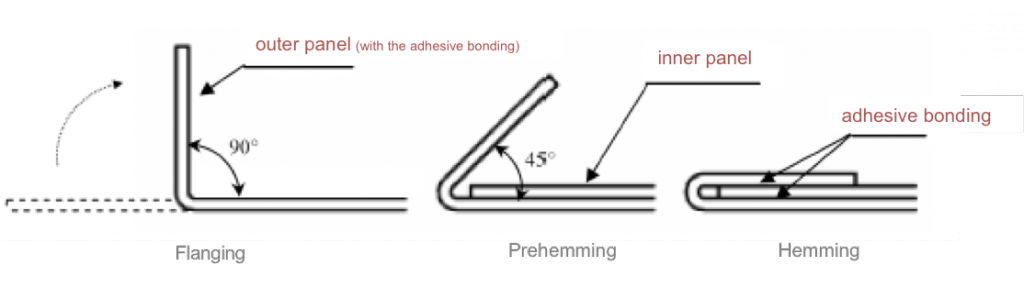

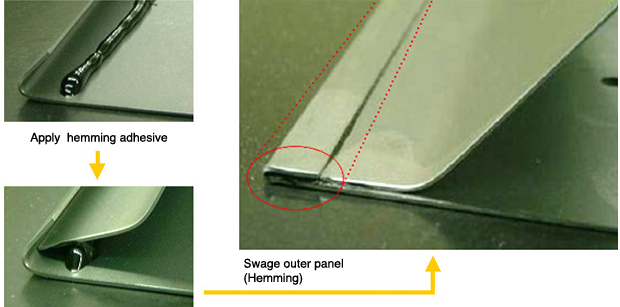

The outer panel (Skin) of the door is attached to the inner structure by a process called hemming to create a hem-flange. Hem-flanges are the edge of metal sheets that are bonded together by bending the edge of one sheet over the edge of another and using a bead of adhesive to seal the sandwiched metal. Take a look at the pictures below to get a quick understanding of what the door looks like that you are spreading. A hem flange is typically 10x the thickness of the sheet metal panel. So lets say the outer door panel is 1mm thick, that means the flange only covers the inner structure by 10mm (less than half an inch). That’s why it is so easy to skin a door!

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

The most common place we see “skinning” occur is when trying to gain access to the rear doors when attempting to gain access. One major reason for this occurring is the incorrect application of the spreading tool. Rather than a complete spread on the initial application of the tool, a rescuer should be aiming to get as close as possible to the NATO bolt. If you can gain a purchase point on the main bulk of the door, chances of “skinning” a door are greatly reduced. Other methods to reduce the risk of “skinning” include unlatching the door, using a ball under the door latch or similar. KJP.

That’s Nader bolt named after auto safety advocate Ralph Nader.