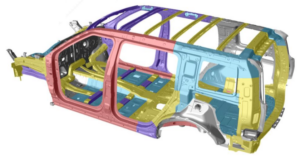

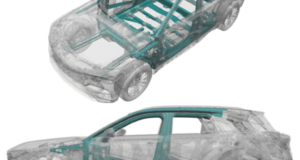

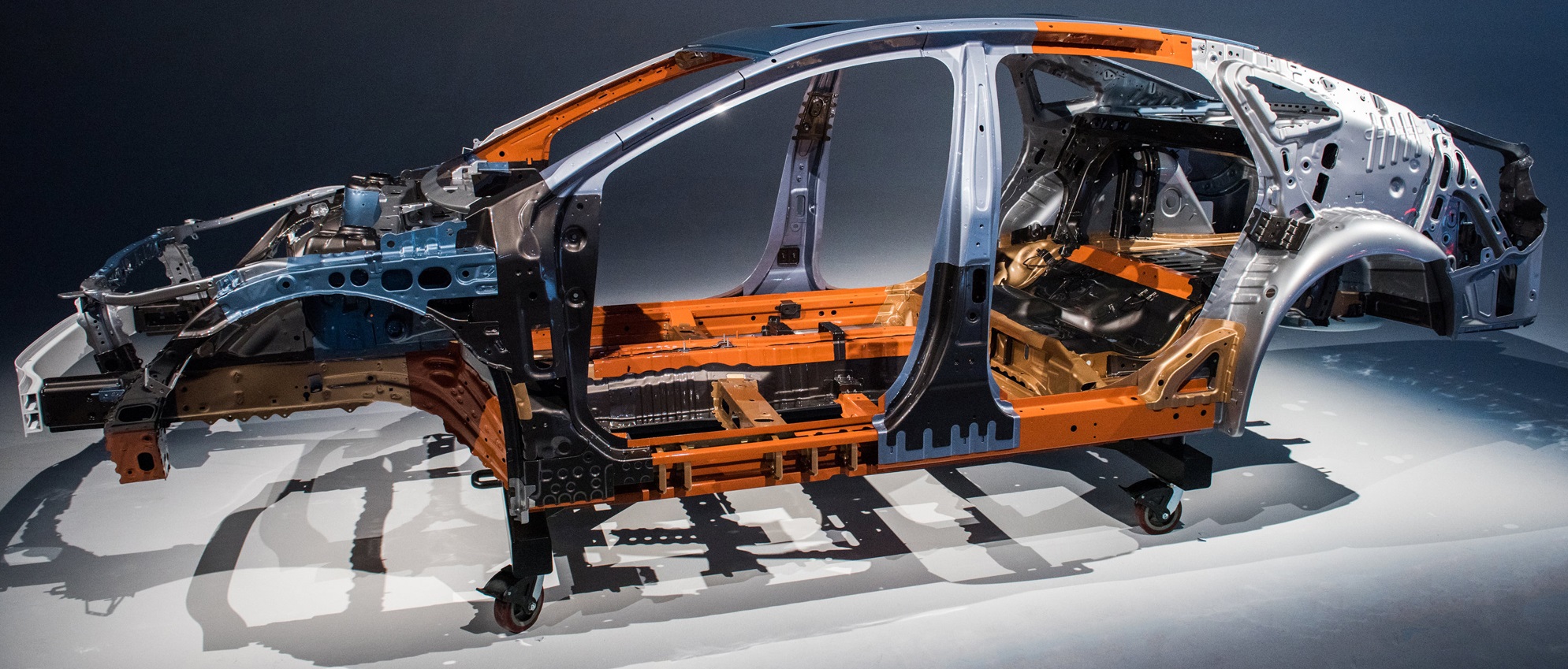

Body Structure

The 2017 Buick Lacrosse is built on the new Epsilon II architecture (’16 Malibu, next-gen Impala, Cadillac XT5). One difference is the LaCrosse’s wheelbase has been stretched by 2.7 inches, mostly by pulling the powertrain and front axle forward. This improves both the visual proportion and stance of the car (dash-to-axle!) while enabling wider front door openings. Learn more about new vehicles with our Vehicle Extrication from inside of the Auto Industry DVD.

The NHSTA and IIHS have tougher roof-crush standards that are met with thinner-section A-pillars that use patch-welded blanks where a super-stiff U-channel gets welded to a lighter-gauge material before it’s stamped into the rough shape of the A-pillar. (A similar strategy is used at the base of the B-pillars.) The body structure breakdown looks like this:

- 25.9 percent high-strength low-alloy steel

- 23.4 percent mild steel

- 16.3 percent ultra-high-strength steel

- 15.1 percent advanced high-strength steel

- 8.7 percent bake-hardenable steel

- 7.7 percent press-hardened steel

- 2.9 percent aluminum (bumper beams, hood, decklid)

The list below shows exactly where the “nearly 300” pounds of weight savings come from:

- 150 pounds: the body-structure lightweighting efforts

- 45 pounds: chassis components

- 36 pounds: closure panels (hood, doors, decklid)

- 32 pounds: sound-deadening materials

- 25 pounds: seats

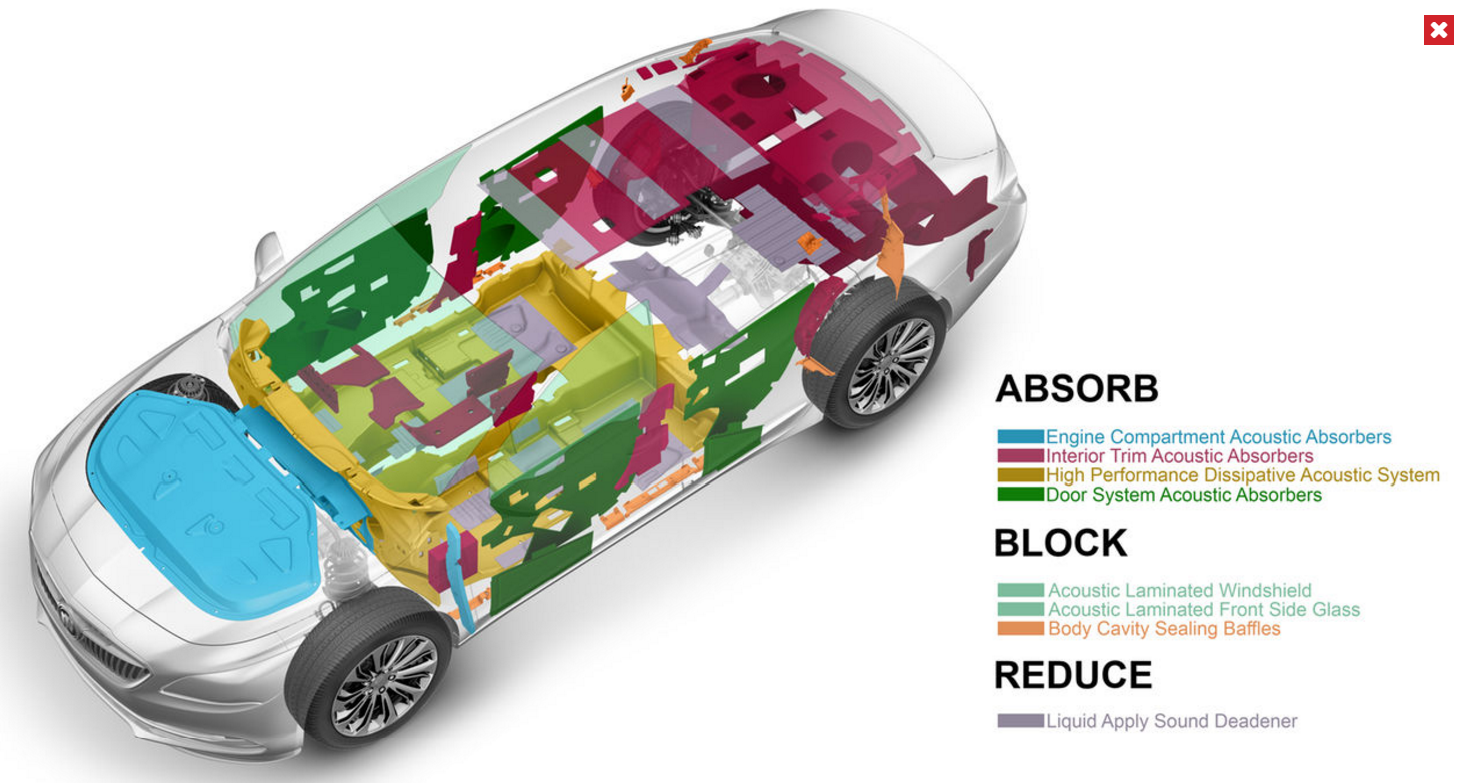

Laminated Side Glass

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles