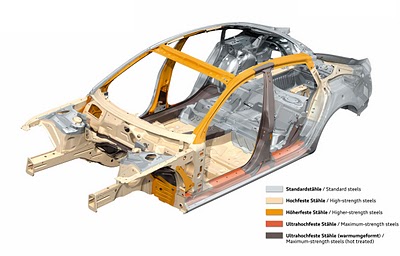

The body-in-white is built using innovative technologies such as hot-shaped steel sheets: tailored blanks of boron alloy steel are heated to 950 degrees Celsius in a continuous furnace and immediately quenched and shaped in a water-cooled die.

Hot-shaped steels are used in the side sills, the longitudinal members, the center console, the B-pillars and the front cross members. Audi uses the ideal material in each area. The front fenders of the A5 Sportback are made of aluminum, and they, too, reduce the weight and contribute to the finely balanced distribution of axle loads.

The joining technologies also underscore the state-of-the-art character of the body structure. A structural adhesive enhances strength in many areas. Innovative laser-beam welding is used at the sills and the doors.

Hot-shaped steels are very light, and profoundly impact the weight balance. The A5 Sportback 2.0 TFSI weighs only 1,500 kilograms (3,307 lb).

Hot-shaped steels are used in the side sills, the longitudinal members, the center console, the B-pillars and the front cross members. The front fenders of the A5 Sportback are made of aluminum.

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles